Chemical

Industry

Industry

PTFE (Teflon®) plays a crucial role in this industriy due to its exceptional properties, ensuring high efficiency and safety in various applications.

Highlighted Features:

- Chemical Inertia: since 1940, it has been used as a sealing and anti-corrosion coating material, resisting almost all chemical agents except alkali metals, fluorine, and strong oxidizers.

- Resistance to Extreme Temperatures: operates efficiently within a range of -200°C to +260°C.

- Low Absorption: unlike other plastics, it has virtually no absorption, increasing its durability.

- Proven Safety: about 35% of the global PTFE consumption is dedicated to the chemical and petrochemical sectors, highlighting its reliability.

Main Applications:

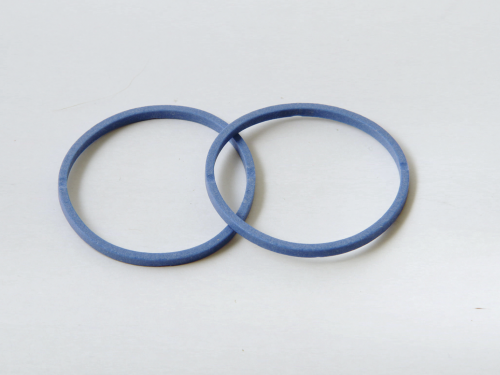

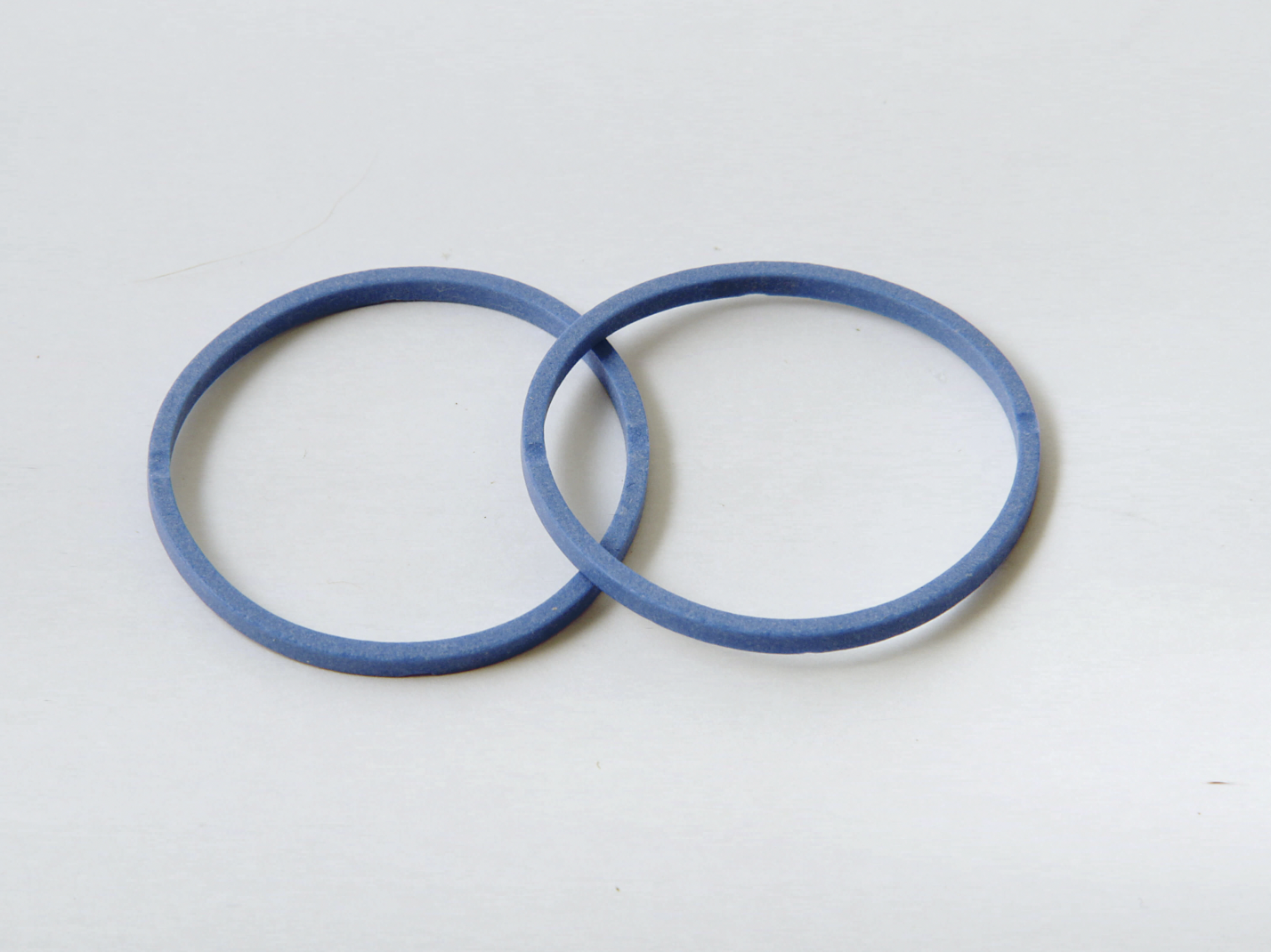

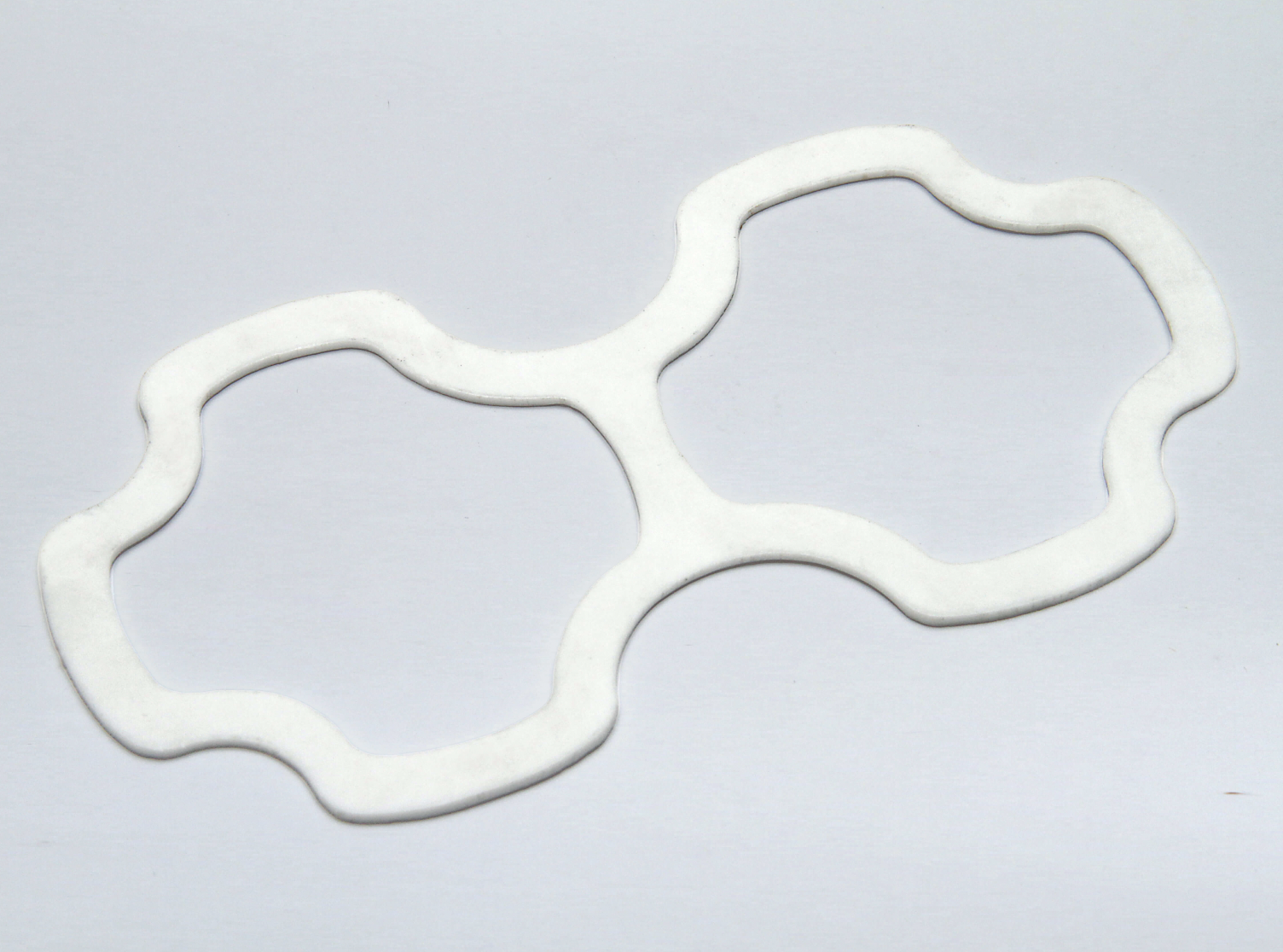

- Gaskets;

- Solid, envelope, and expansion joints;

- Valves, rings, washers, diaphragms, and membranes;

- Pile linings;

- Tank coatings;

- High-voltage electrical insulators.

Related Products:

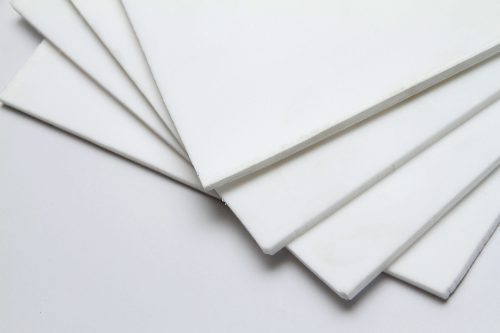

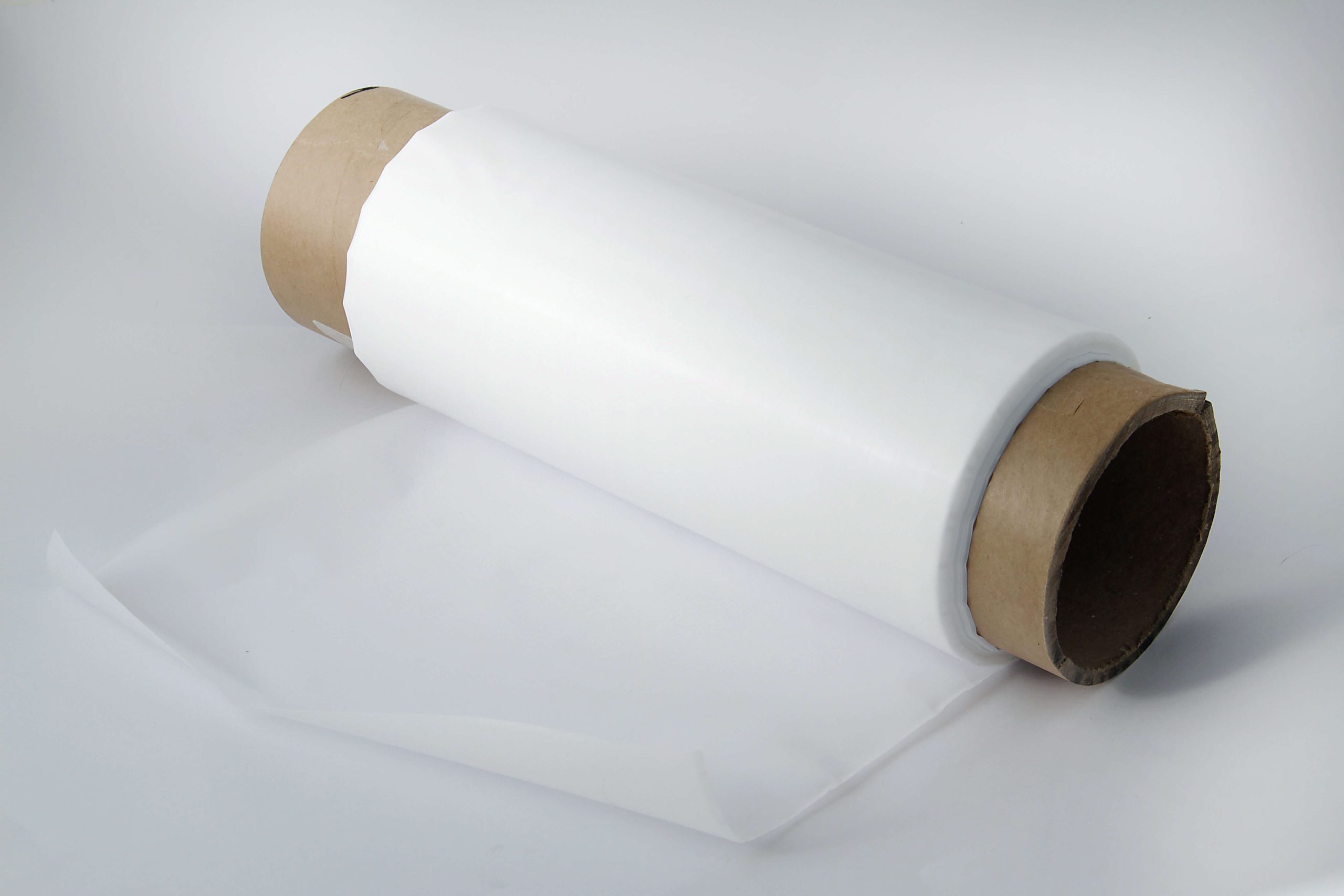

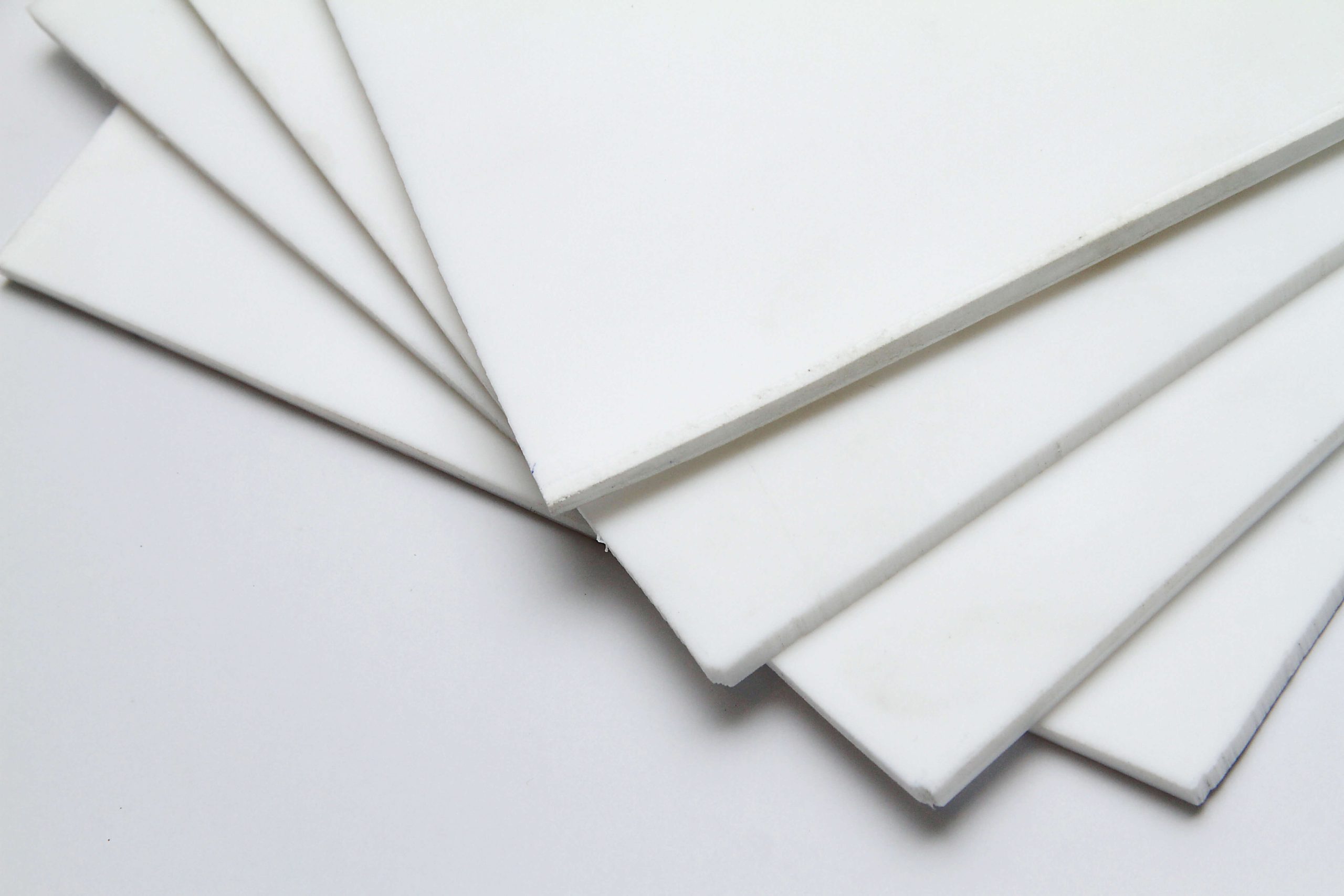

- Chemically treated skived sheets: for refractory tower and tank coatings;

- Sheets: for manufacturing flange gaskets and seals;

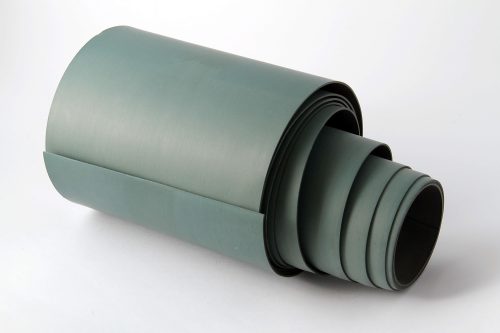

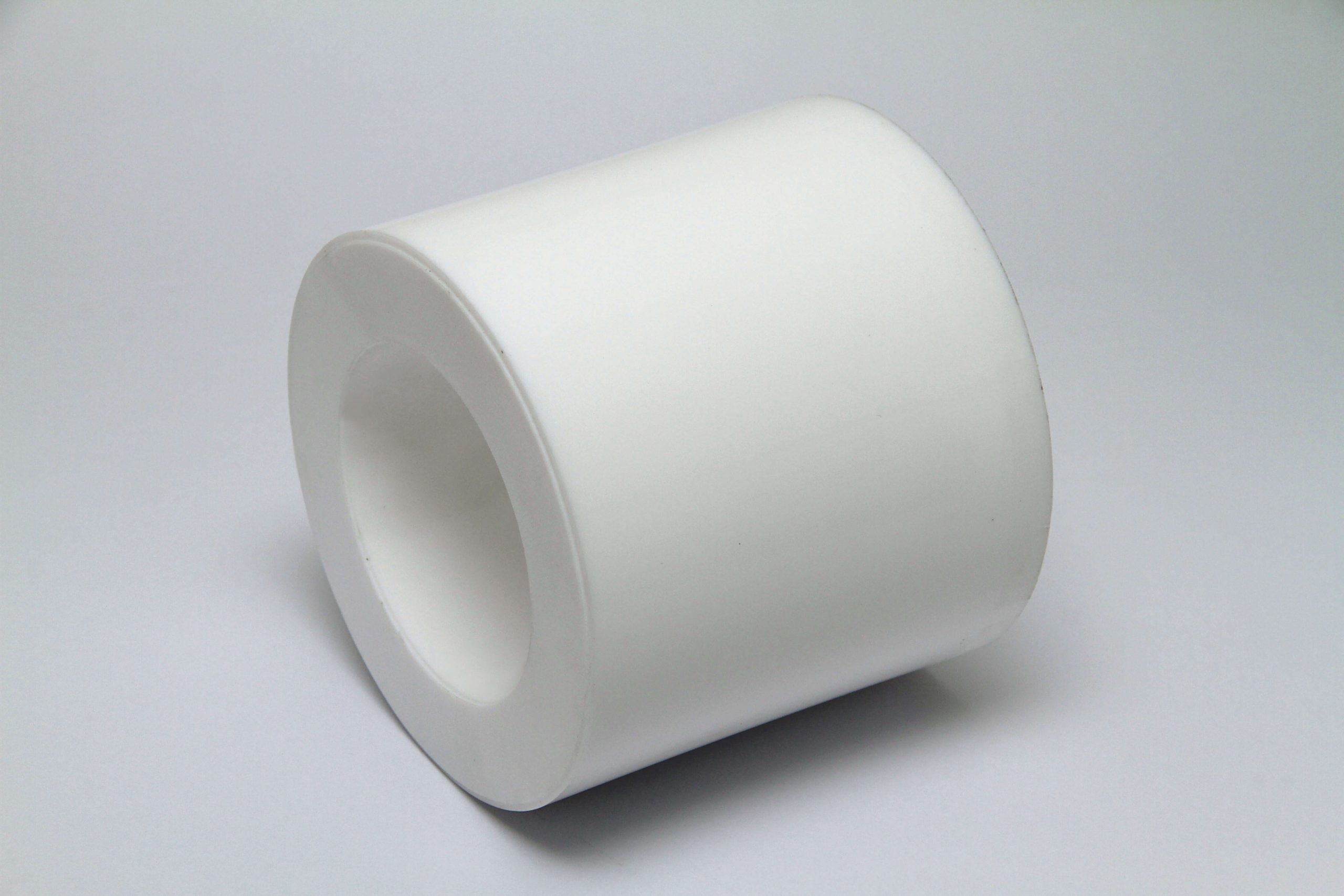

- Bushings: for producing envelope and solid joints;

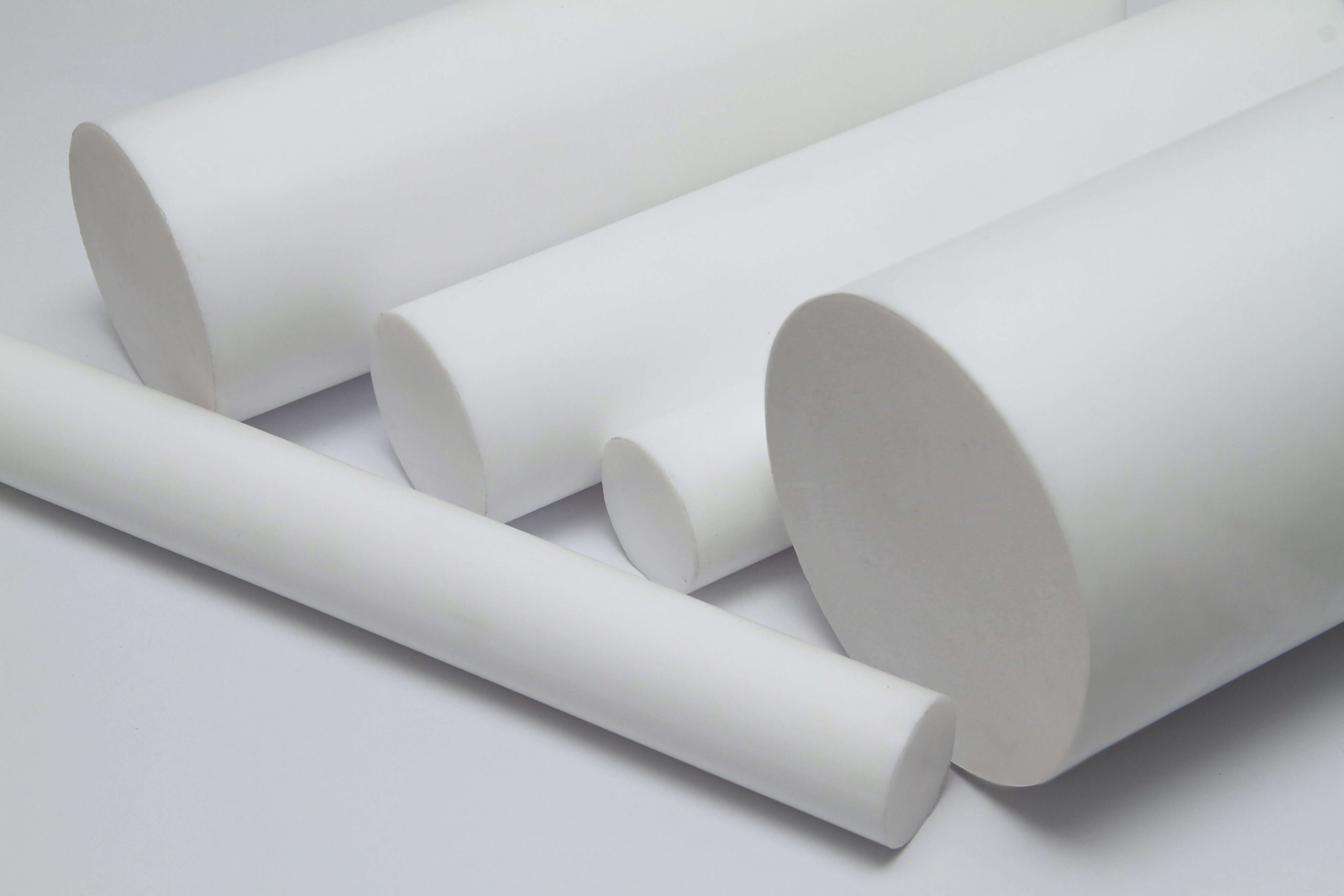

- Rods: for manufacturing electrical insulators and technical repairs.