Oil&Gas

Industry

Industry

The technical parts machined in PTFE by Tecnoflon are widely used in the Oil & Gas due to its exceptional resistance to high temperatures, low coefficient of friction, self-lubricating properties and electrical insulation capacity.

Main applications | Machined from PTFE for Oil & Gas:

Tecnoflon develops customized machined solutions, according to customer specifications, including:

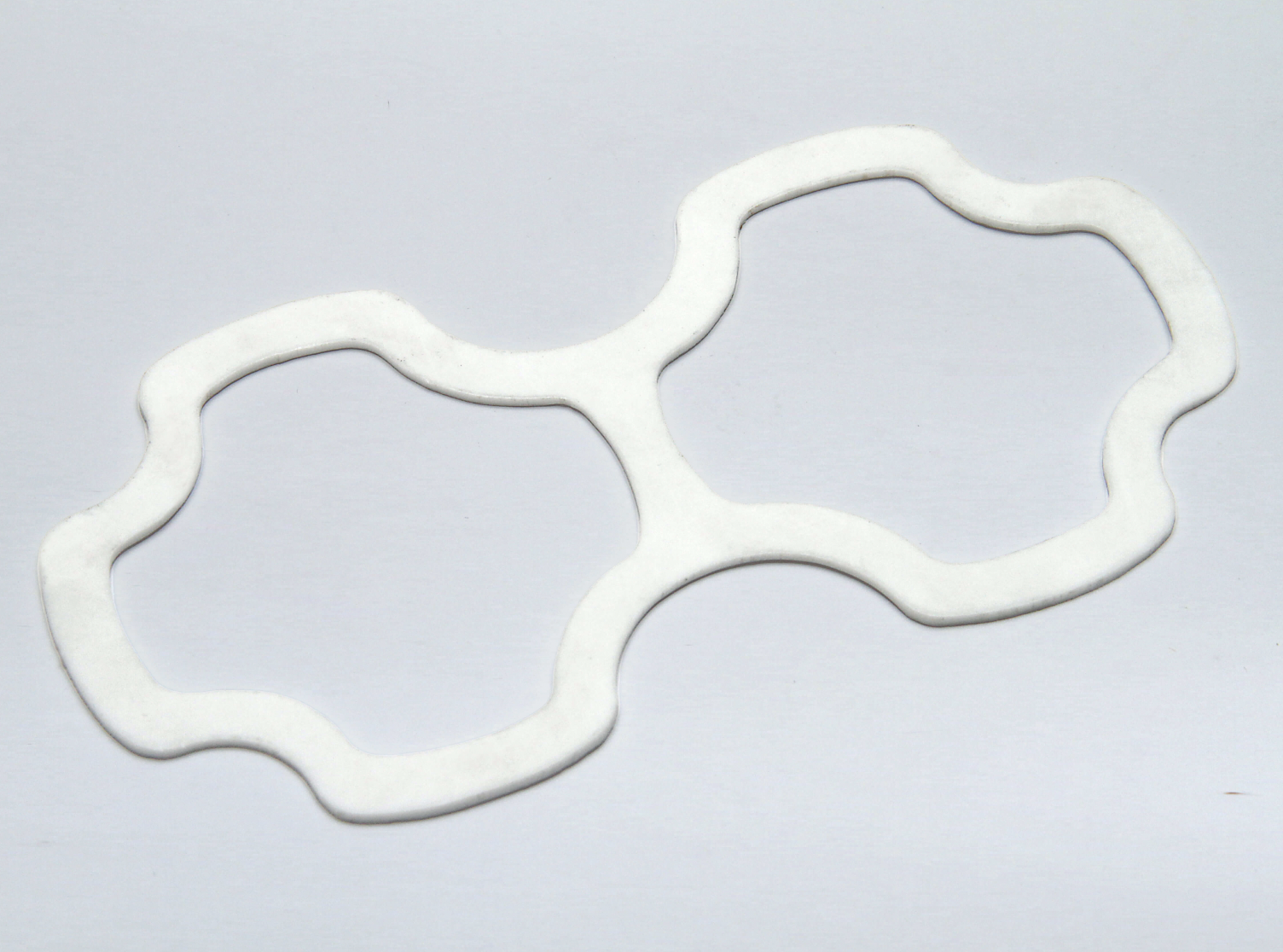

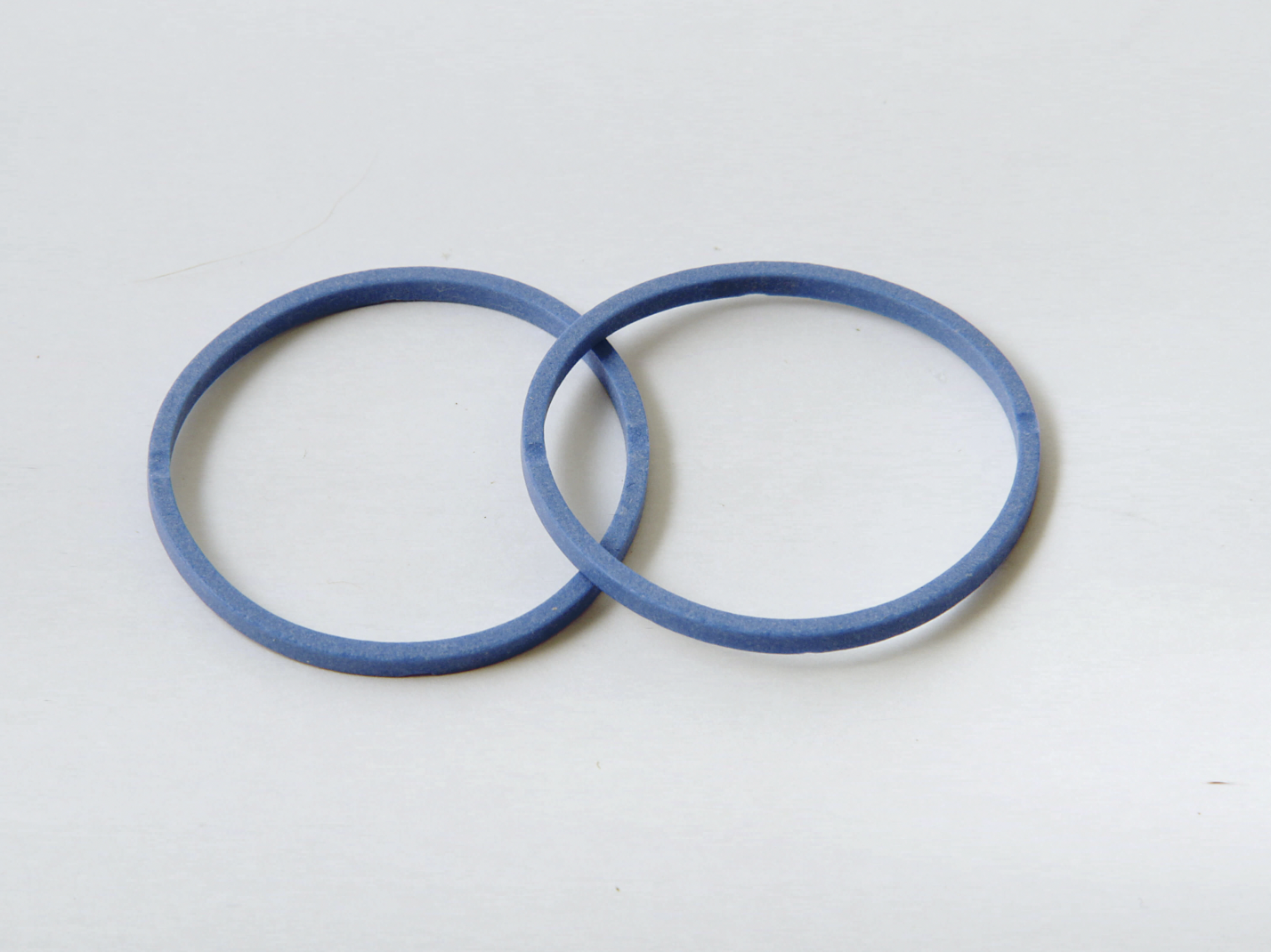

- PTFE gaskets for static and rotating seals in contact with aggressive, corrosive chemicals, gases, solvents and oxygen;

- PTFE gaskets, seats and balls for sealing and movement applications;

- Valve repairs, meeting the need for greater material resistance;

- PTFE tubes for pipe linings, ensuring protection against corrosion and wear.

Main applications | Semi-finishedPTFE for Oil & Gas:

Tecnoflon offers a wide variety of PTFE semi-finished products that can be produced to order, meeting the most diverse applications and needs.

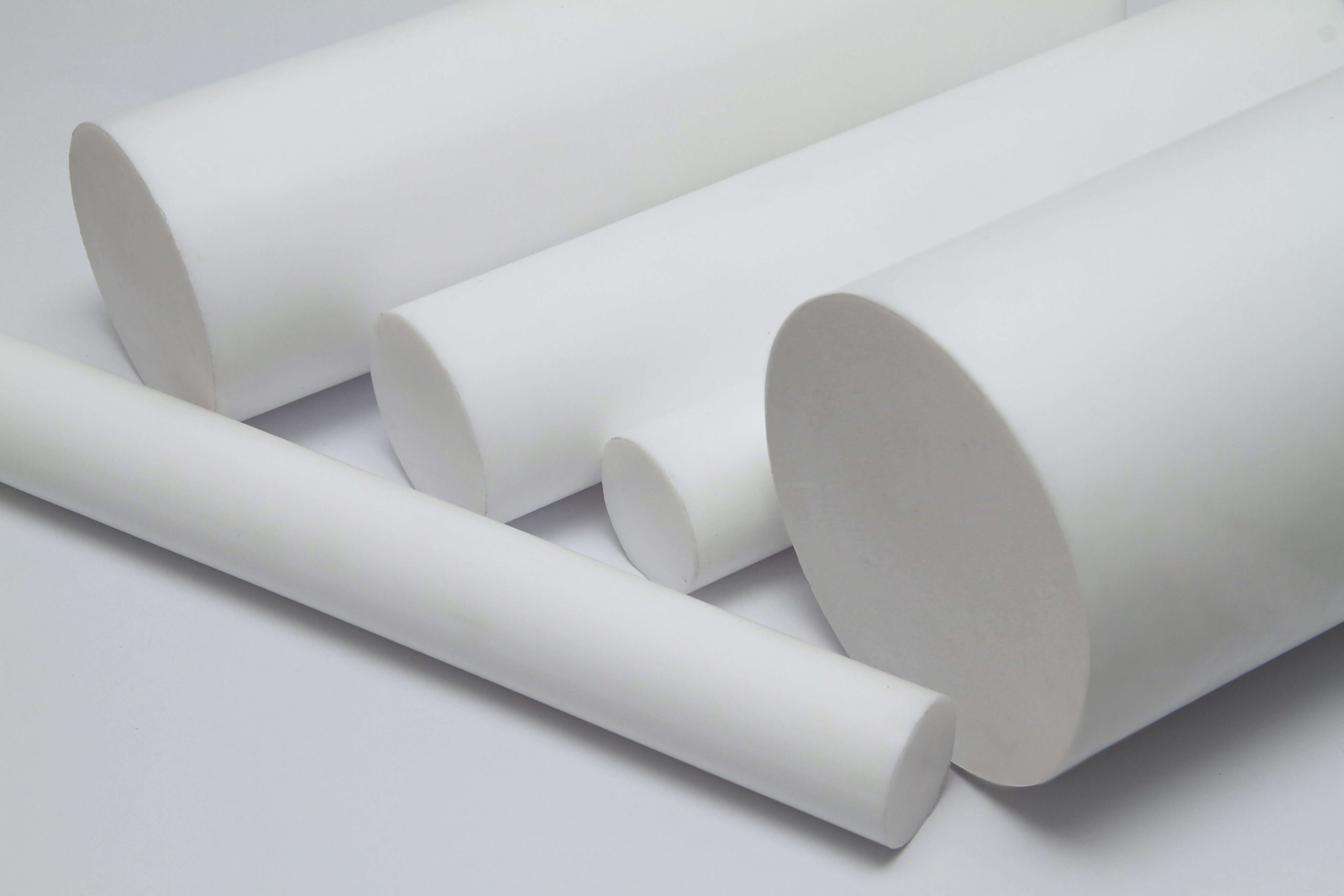

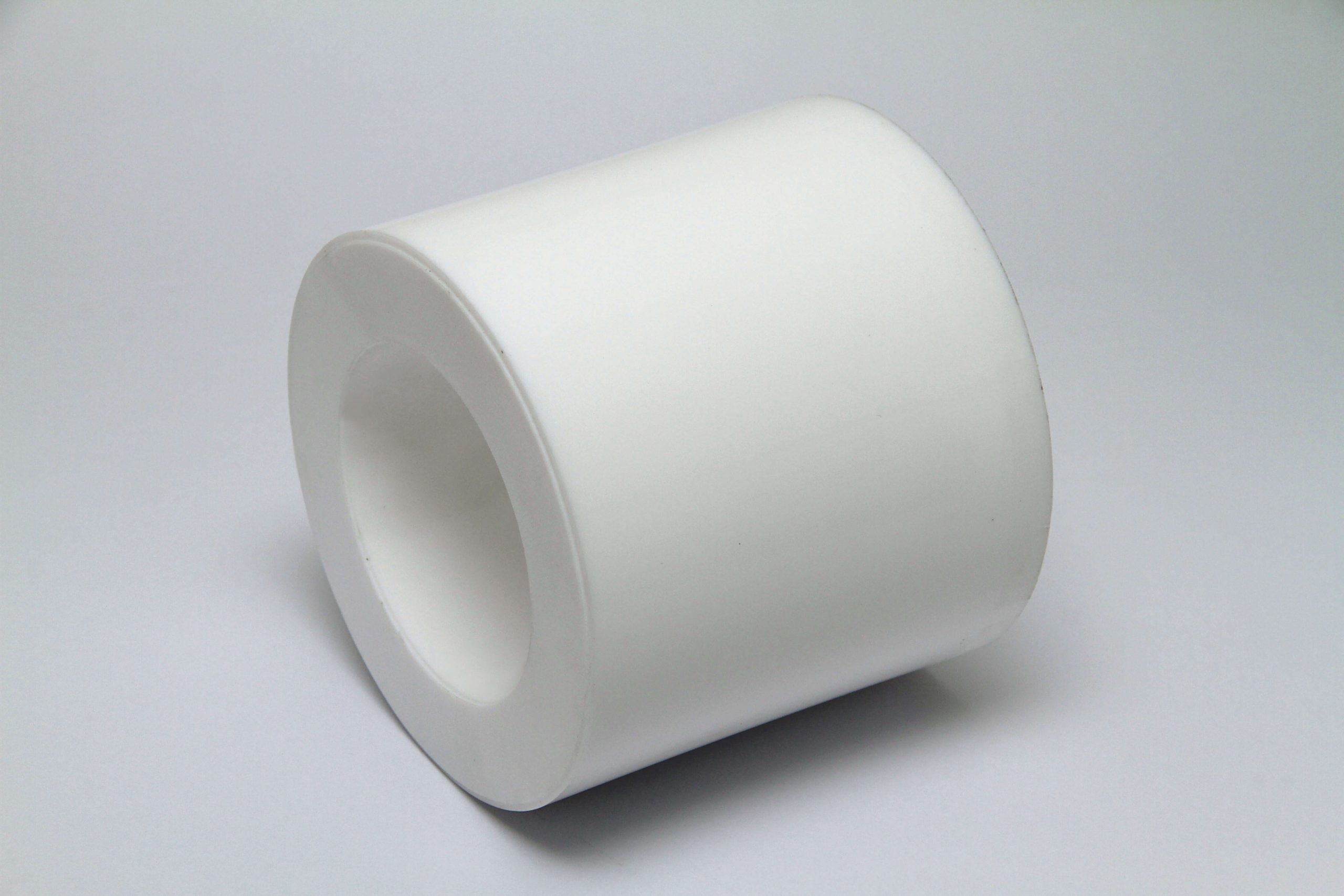

- Rods and Bushings (Pure PTFE or PTFE Compounds): used in the manufacture of technical parts, such as valve seats, balls, sealing gaskets, distillation tower fillings and components for electrical insulation. Suitable for a wide range of industrial applications.

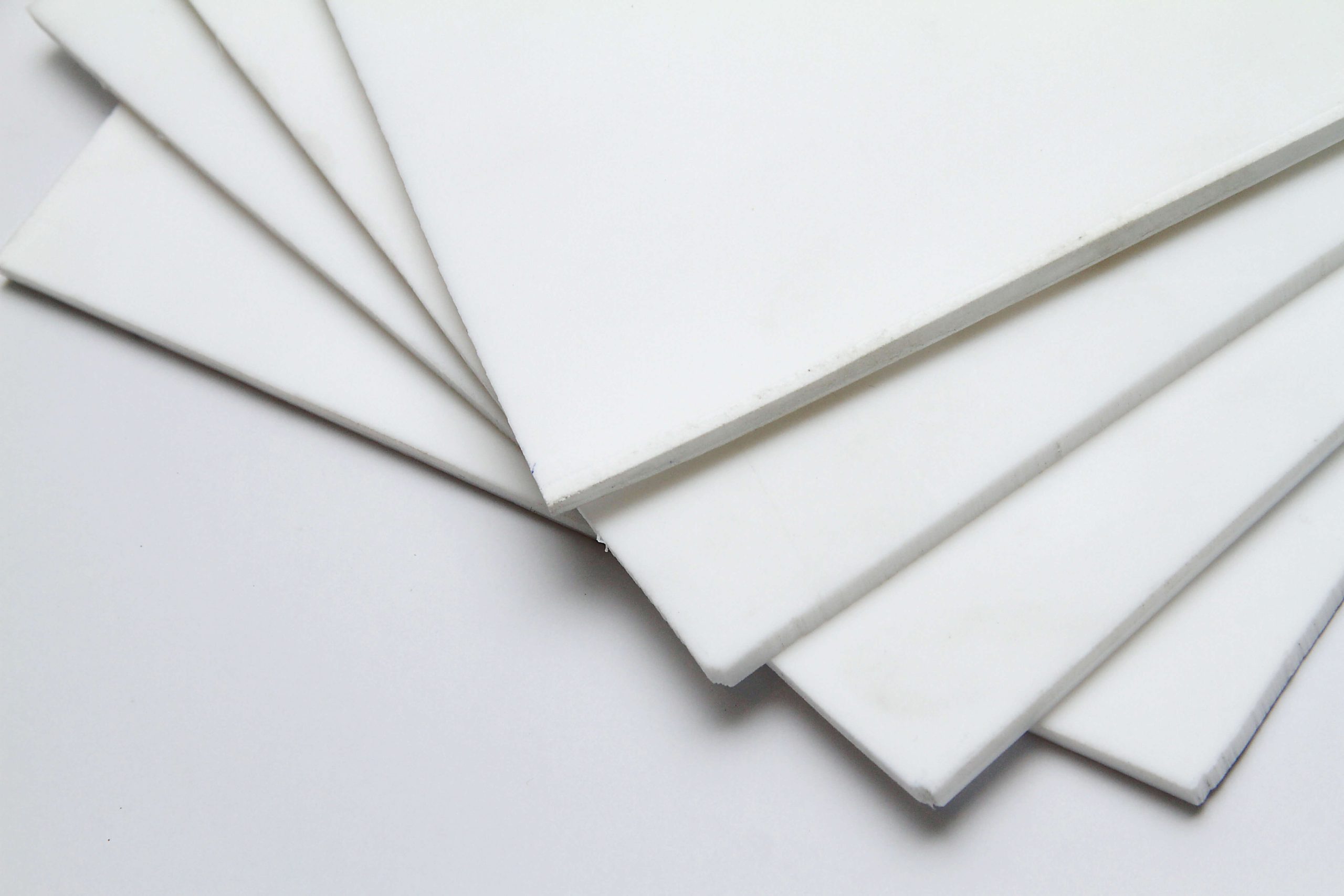

- PTFE sheets: used in the manufacture of sealing joints for pipe flanges, sliding supports in gas pipeline pipe cradles, supports for metallic structures and vibration dampers.

Related products:

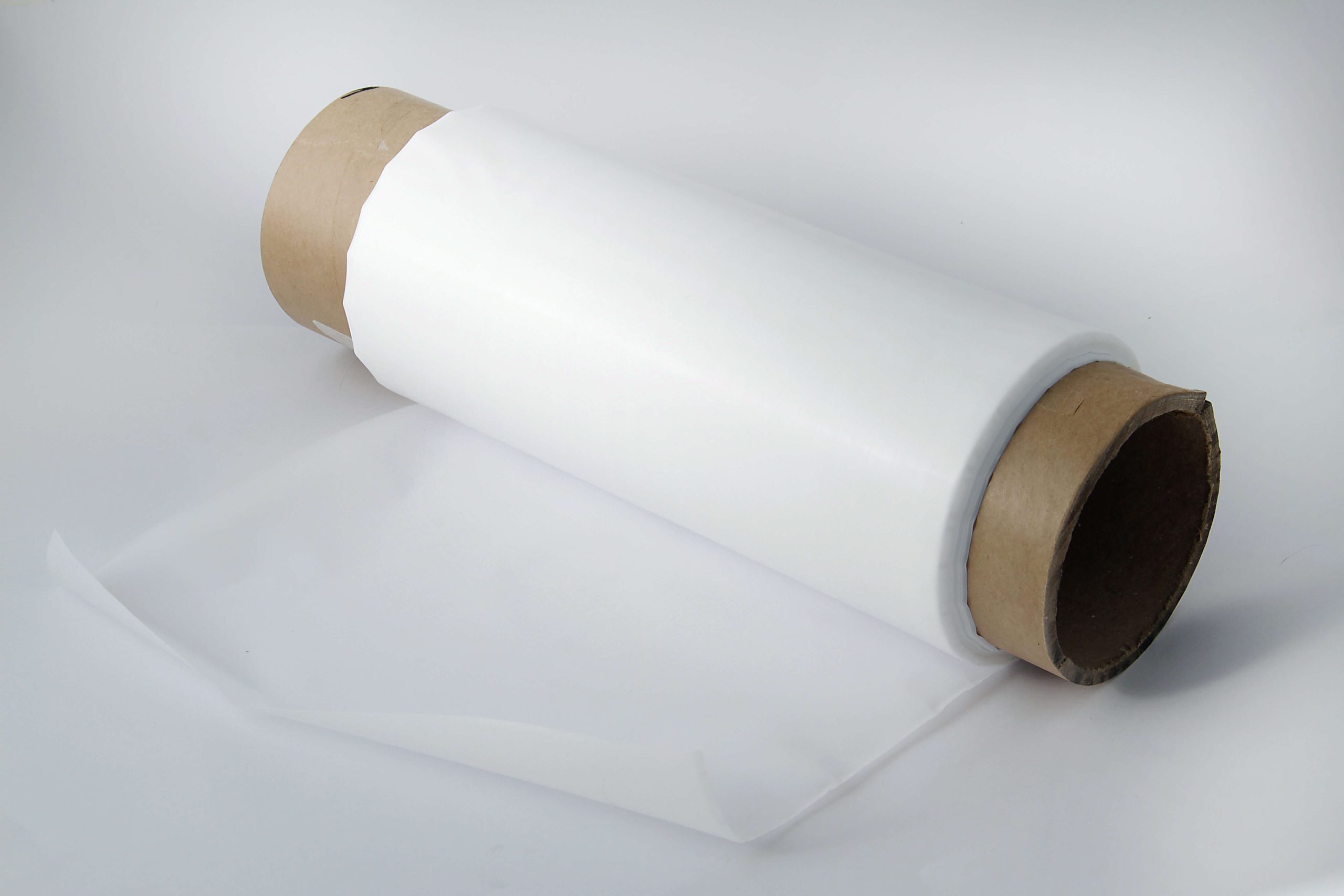

- Skived sheets with chemical treatment for specific coatings;

- Sheets for manufacturing pipe flange joints;

- Bushings for the production of technical parts, seats and valve bodies;

- Rods for manufacturing electrical insulators and repair maintenance.